嘉盛分类

Product center

CONTACT

联系我们

潘国秋:18015032539

手 机:15995079857

电 话:0519-88908255

传 真:0519-88905276

地 址:常州天宁区郑陆镇舜南村

手 机:15995079857

电 话:0519-88908255

传 真:0519-88905276

地 址:常州天宁区郑陆镇舜南村

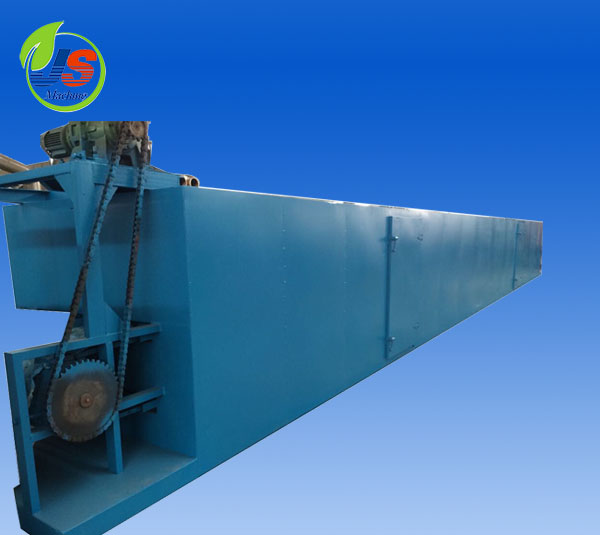

菊花带式干燥机

作者: 发布于:2018-12-14 14:45:27 点击量:

产品简介:

用途

带式干燥机是常用的连续式干燥设备,可广泛应用于化工、食品、医药、建材、电子等行业,特别适合于透气较好的片状、条状、颗粒状物料的干燥,对滤饼类和膏状物料,也可通

免费热线:18015032539

菊花带式干燥机的详细资料:

用途

带式干燥机是常用的连续式干燥设备,可广泛应用于化工、食品、医药、建材、电子等行业,特别适合于透气较好的片状、条状、颗粒状物料的干燥,对滤饼类和膏状物料,也可通过造粒机或挤条机制成型后进行干燥。

典型产品

脱水蔬菜、颗粒饲料、味精、鸡精、椰蓉、有机颜料、 合成橡胶、丙烯纤维、药品、药材、小木制品、塑料制品、 电子元器件老化、固化等。

技术参数

带式干燥机是常用的连续式干燥设备,可广泛应用于化工、食品、医药、建材、电子等行业,特别适合于透气较好的片状、条状、颗粒状物料的干燥,对滤饼类和膏状物料,也可通过造粒机或挤条机制成型后进行干燥。

典型产品

脱水蔬菜、颗粒饲料、味精、鸡精、椰蓉、有机颜料、 合成橡胶、丙烯纤维、药品、药材、小木制品、塑料制品、 电子元器件老化、固化等。

技术参数

| 型 号 | DW-1.2-8A | DW-1.2-10A | DW-1.6-8A | DW-1.6-10A | DW-2.0-8A | DW-2.0-10A | |

| 单元数 | 4 | 5 | 4 | 5 | 4 | 5 | |

| 干燥段长(m) | 8 | 10 | 8 | 10 | 8 | 10 | |

| 铺料厚度(mm) | ≤60 | ||||||

| 使用温度(℃) | 50-140 | ||||||

| 蒸汽压力(MPa) | 0.2-0.8 | ||||||

| 蒸气耗量(kg/h) | 120-300 | 150-375 | 150-375 | 170-470 | 180 | 500 | |

| 干燥时间(h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | |

| 干燥强度(kg水/h) | 6-30 | ||||||

| 装机功率(kw) | 11.4 | 13.6 | 11.4 | 13.6 | 12.5 | 14.7 | |

| 外形尺寸(m) | A | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 |

| A1 | 2.28 | 2.28 | 2.68 | 2.68 | 3.2 | 3.2 | |

| B | 8.0 | 10.0 | 8.0 | 10.0 | 8.0 | 10.0 | |

| B1 | 9.5 | 11.5 | 9.5 | 11.5 | 9.5 | 11.5 | |

| C | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

- 上一个:饲料带式干燥机

- 下一个:咖啡粉高效沸腾干燥机

相关产品