Products

Product center

CONTACT

contact us

Ms. Amy Chen:+86 18015032539

Phone:+86 15995079857

Tele:+86 519 88908255

Fax:+86 519 88905276

Mail:amy@czjsmachine.com

Address:Shunnan Village,Zhenglu Town,Tianning District,Changzhou City,Jiangsu Province,China

Phone:+86 15995079857

Tele:+86 519 88908255

Fax:+86 519 88905276

Mail:amy@czjsmachine.com

Address:Shunnan Village,Zhenglu Town,Tianning District,Changzhou City,Jiangsu Province,China

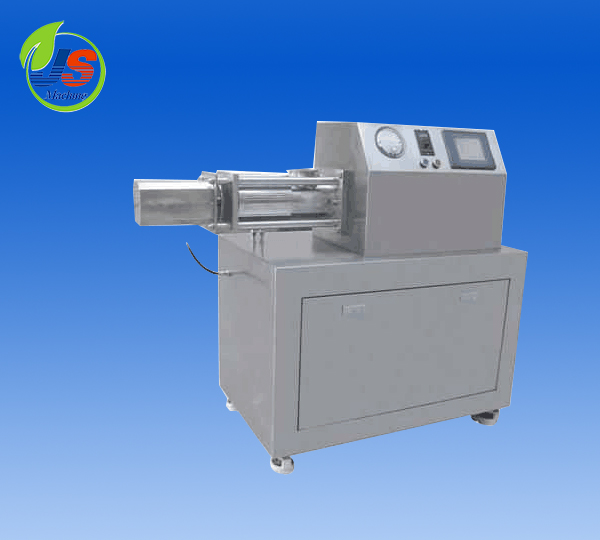

Calcining kiln

Location:Home > Product > Calcining kilnCalcining kiln

Author: Released:2021-08-12 08:18:35 Click:

Introduction:

NO Name 1 Furnace tank specification Diameter ¢ 377mm * 7000m (diameter * length) thickness 8mm 2 Gas hot air furnace 400000Kcal

Hotline:18015032539

Calcining kilnData:

| NO | Name | |

| 1 | Furnace tank specification | Diameter ¢ 377mm * 7000m (diameter * length) thickness 8mm |

| 2 | Gas hot air furnace | 400000Kcal |

| 3 | Treatment capacity | 2 T / h (heating process time: 30 min; Bulk specific gravity of materials (1.4g / cm3) |

| 4 | Material of furnace tank | SUS304 |

| 5 | Design Temperature | 450℃ |

| 6 | Material trend | There are inlet, constant temperature zone and outlet |

| 7 | Rated voltage | 380V 3P 50HZ |

| 8 | Control accuracy: | ±1℃ |

| 9 | control mode | Xiamen Dedian intelligent program instrument PID + touch screen, power modulator control and voltage regulation |

| 10 | Screw speed | 1-5r / min, when the speed stops, it will give an alarm |

| 11 | Main drive motor | The motor power is 1.1KW, and the gear transmission system is adopted |

| 12 | Furnace inclination (tube) | 0-2 ℃ (based on axial horizontal line) |

| 13 | Heating element material | 0Cr27Al7Mo2 |

| 14 | Arrangement of heating elements | Bottom heating |

| 15 | Number of temperature measurement / control zones | Two point temperature control. |

| 16 | Refractory fiber | Refractory cotton + backing (total thickness: 150 mm) |

| 17 | Thermocouple type | K scale thermocouple |

| 18 | Temperature rise of furnace surface | ≤ ambient temperature + 20 ℃ |

| 19 | Cooling mode | Air cooling |

| 21 | Feeding mode | Screw feeder |

| 22 | Supporting device: | The transmission shaft adopts two-point support and flexible support |

1、 The equipment mainly consists of steel structure furnace body, thermal insulation material, furnace tank, stainless steel auger, transmission system, heating and electrical temperature control system and cooling system. 1. The main frame of furnace body is made of channel steel and I-beam. The four side steel plate is welded by Q235 steel plate. The overall structure is firm and reliable, and all welds are even and smooth, without pores, inclusions, lack of fusion and other defects. The overall strength is good, not easy to deform, and the appearance is smooth and smooth. The inner and outer walls of the furnace shell are primed with iron red phenolic paint, and the shell is evenly sprayed with phenolic aluminum powder paint, so as to effectively prevent the furnace shell from rusting. The bottom bearing body is composed of two longitudinal beams and several beams, with thick steel plate on the surface. Its rigidity ensures no deformation under full load. Compared with the traditional frame structure, the structure strength of the beam bearing structure is obviously enhanced, and the deformation coefficient is basically unchanged. 2. All fiber furnace body: (1) steel framework: factors such as structural strength, deflection and thermal expansion should be considered in the design of furnace body framework. In this scheme, the steel framework of furnace body is welded by large section steel and steel plate or anchored by high-strength bolts to form a high-strength truss rigid framework structure with good air tightness. The influence of thermal expansion is fully considered in the design, so that the steel structure is light and durable without deformation. Considering that the furnace expands / contracts with the change of temperature when it is working. The steel structure of furnace body has the function of expansion / contraction absorption. (2) Furnace lining: the furnace body with full refractory fiber composite structure (flat fiber blanket + fiber module) weighs only 1 / 20 of the refractory brick furnace body, but it can save energy by 25-30%. This kind of furnace lining also has the characteristics of simple installation, short construction time and long service life. Furnace wall and furnace bottom: the composite structure of 100 mm thick fiber combination module and 50 mm thick ordinary fiber blanket is selected. The total fiber thickness is 150 mm. The arrangement mode of fiber combination module is "soldier array" - along the compression size of the module. Joint part of furnace wall and furnace top: in order to prevent through joint in this part, the joint between wall and wall, wall and top adopts staggered joint connection between ceramic fiber module and backing blanket. At the same time, in order to prevent the high-temperature shrinkage of the joint of ceramic fiber module in the hot surface layer, a compensation joint is set at the joint of the wall top, and the fiber blanket of the same material as the module is folded in half, maintaining a compression ratio of more than 30%, and forcibly inserting, so as to ensure the high-temperature sealing effect of the part. Furnace end face: the composite structure of fiber combination module with thickness of 100 mm and fiber blanket with thickness of 50 mm is selected. The total fiber thickness is 150 mm. The arrangement mode of fiber combination module is "soldier array" - along the compression dimension of module. The fiber around the furnace door is made into a ladder type structure, which can make the furnace door and the furnace mouth structure form a double structure of double side sealing of hot channel and soft and hard sealing of cold channel when the furnace door is closed, so as to ensure the good sealing of the furnace door. The multilayer refractory fiber blanket is laid on the inner side of the lining steel plate, and then the fiber blanket is installed with the heat-resistant steel bolt assembly to make the folded unit block to form the combined furnace lining. The folding unit block is compressed and packed in advance, the packing belt is cut off after installation, and the fiber blanket is springed open to ensure the overall sealing of the furnace lining. The heat-resistant steel bolt assembly is only installed at 1 / 4 of the thickness of the furnace lining, which avoids the heat short-circuit loss and makes the thermal conductivity of the combined furnace lining and the laminated structure almost the same. There is no obvious gap affecting the normal performance of the refractory fiber module in use. 3. Furnace tank (1) the furnace tank is made of high temperature stainless steel, which makes the materials pass through the furnace tank at a uniform speed for radiation heating, so that the materials are heated more evenly in the heating process.

2、 6. Heating element and control system 1. Heating element and installation (1) heating element 0cr27al7mo2 resistance bar is divided into two zones, which are controlled independently, and the power of each zone is reasonably distributed according to the uniformity of furnace temperature.

3、 (2) the waveform resistance tape is laid in the furnace, which will not produce thermal short circuit phenomenon; it is convenient to replace and maintain. Its service life is guaranteed. 2. Electric control system

2.1 the control system is composed of control cabinet, temperature control system, temperature record, power controller, control appliance and measuring transmission device.

2.2 the control cabinet adopts the domestic popular vertical standard cabinet, and the appearance of the control cabinet is sprayed with computer color or light camel color. The electric control panel is equipped with ammeter, voltmeter, temperature controller, temperature recorder, indicator light and button.

two point three Xiamen Dedian instrument is used as the temperature control instrument for temperature control. The instrument is a high-performance programmable PID programmable controller. It has perfect functions, excellent performance, delicate design, super bright double four digit, super bright character display and many status displays, six groups of expert PID parameter pre storage, more advanced regional PID algorithm, with manual, power failure and fault protection, analog transmission and communication It has three independent event outputs and four external Di switch inputs. It can display the theoretical value and the measured value according to the set temperature. The temperature control system also has the function of over temperature sound and light alarm.

two point five Power controller is the core component of temperature control. The contactor type and common thyristor type used in the past can no longer meet the higher requirements of customers for furnace temperature control. Moreover, the old control mode is noisy and has great impact on the power grid. Therefore, our company selects advanced AC power controller as the main control body, which integrates three-phase power regulation and voltage regulation, 4-20 Ma signal input, with PLL synchronization circuit, automatic phase discrimination, power on slow start, radiator overtemperature detection, over-current protection, current limit, constant current output, phase missing protection, working state indication and other functions, using high-power thyristor module drive, heat dissipation air cooling unit using special insert radiator and fan, which is more conducive to the heat dissipation of the module and greatly improves the efficiency The service life of the module is prolonged, and the over temperature alarm function of the module is also provided.

two point six The control appliance includes air switch, contactor, intermediate relay, current and voltage meter, indicator light and button. Chint low voltage appliance is used as the connection of control circuit. The power supply of control appliance is controlled by 220 V voltage, and an emergency stop button is installed on the main control panel as the main circuit of all 220 V power supply. In case of emergency, all control power supply and power supply can be cut off quickly Output.

two point seven It includes thermocouple, compensation wire and instrument, that is, thermocouple measures the temperature in the furnace, which is fed back to the instrument through the compensation wire, and the instrument automatically folds the temperature control. The thermocouple and compensation wire are K-type ceramic thermocouple, which has the advantages of good linearity, large thermoelectromotive force, high sensitivity, good stability and uniformity, strong oxidation resistance, and can be used It is widely used in oxidizing inert atmosphere.

2.8 the on-off indication of ammeter, voltmeter and electric heating element shall be set for heating control, with power on interlock protection and safe grounding measures to ensure safe use; all electrical appliances, instruments, keys, etc. on the control cabinet panel shall be clearly marked, and the connected cables and wires shall have unique wire number corresponding to the terminals in the wiring box or main cabinet, so as to facilitate maintenance.

2.9 all mechanical transmission parts are equipped with limit protection and interlock protection to ensure safe use. The action of furnace door and trolley can be controlled by remote controller according to actual use. With the remote control device, the workers can directly observe the feeding and discharging at any position in front of the furnace, which is not affected by the visual effect.

2.11. Safety measures

2.11.1. Electrical safety measures: all cables in the equipment are laid in trunking or through pipes, and connected to the main cabinet or specified wiring box. The connected cables have unique wire number corresponding to the terminals in the wiring box or main cabinet. In addition, all exposed mechanical transmission parts in the equipment, including the power input and output ends, are equipped with protective covers and warning signs

2.11.2. Power safety measures: the control execution system adopts high-power bidirectional thyristor combination unit, and the safety factor of thyristor is more than 2.5 times. Aluminum alloy heat dissipation and a full set of air cooling system, at the same time, automatic switch and rapid melting device are used for secondary protection to ensure the normal operation of SCR. Each group of electric heating element is equipped with ammeter, voltmeter, on-off indication of electric heating element, and three-phase voltage transfer switch to know the power supply situation in time.

Related products